Catal. Sci. Technol., 2016, Advance Article

DOI: 10.1039/C6CY00855K, Communication

DOI: 10.1039/C6CY00855K, Communication

Nicholas J. Weise, Syed T. Ahmed, Fabio Parmeggiani, Elina Siirola, Ahir Pushpanath, Ursula Schell, Nicholas J. Turner

An industrial-scale method employing a phenylalanine ammonia lyase enzyme

An industrial-scale method employing a phenylalanine ammonia lyase enzyme

Intensified biocatalytic production of enantiomerically pure halophenylalanines from acrylic acids using ammonium carbamate as the ammonia source

*Corresponding authors

aManchester Institute of Biotechnology & School of Chemistry, University of Manchester, 131 Princess Street, Manchester, UK

E-mail: nicholas.turner@manchester.ac.uk

E-mail: nicholas.turner@manchester.ac.uk

bJohnson Matthey Catalysts and Chiral Technologies, 28 Cambridge Science Park, Milton Road, Cambridge, UK

Catal. Sci. Technol., 2016, Advance Article

DOI: 10.1039/C6CY00855K

SEE

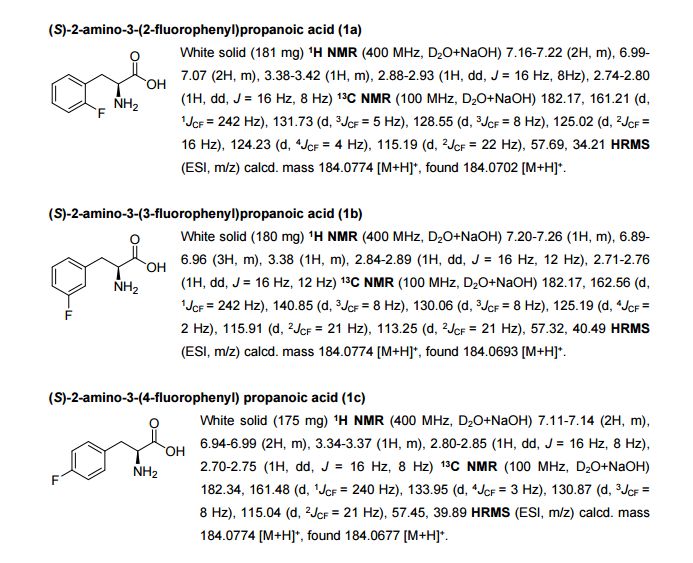

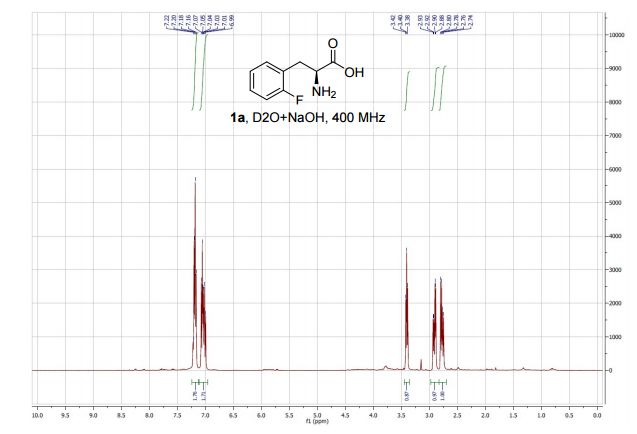

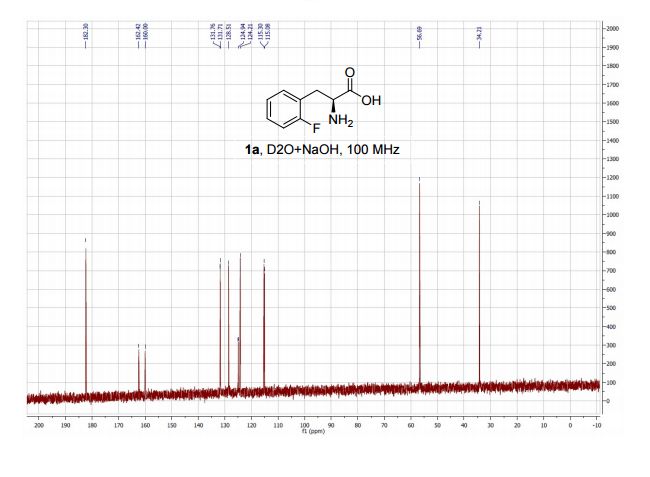

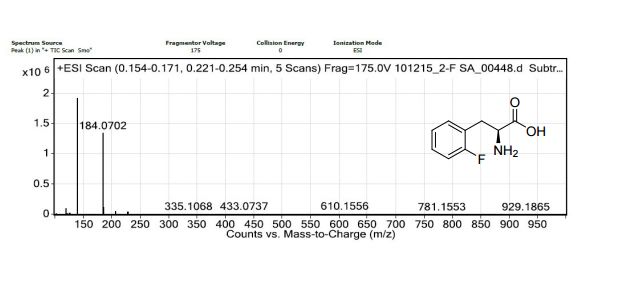

An intensified, industrially-relevant strategy for the production of enantiopure halophenylalanines has been developed using the novel combination of a cyanobacterial phenylalanine ammonia lyase (PAL) and ammonium carbamate reaction buffer. The process boasts STYs up to >200 g L−1 d−1, ees ≥ 98% and simplified catalyst/reaction buffer preparation and work up.

///////Intensified, biocatalytic production, enantiomerically pure, halophenylalanines, acrylic acids, ammonium carbamate, ammonia source