Spray Drying

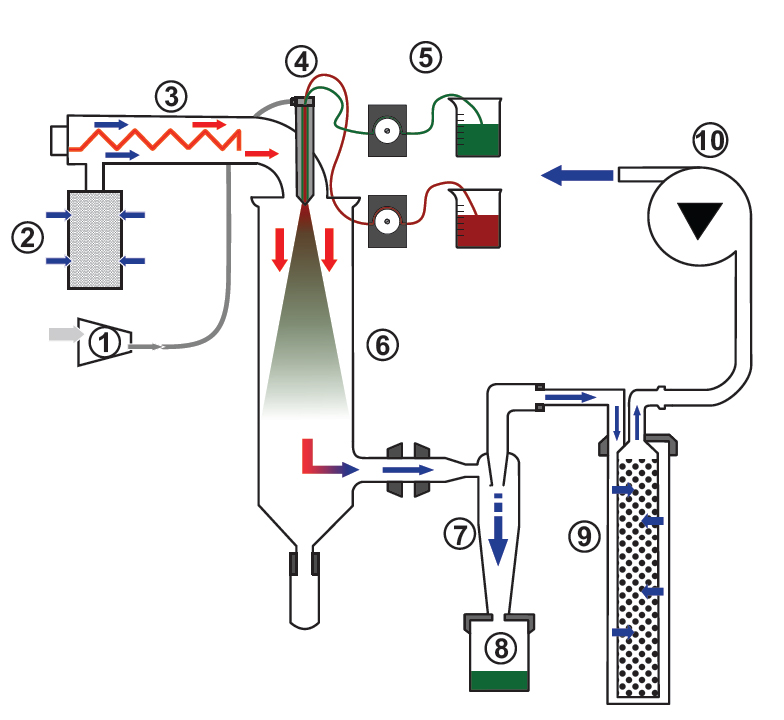

Figure – 1 Main process stages involved in spray drying process[3

Spray drying is the continuous transformation of feed from a fluid state into dried particulate form by spraying the feed into a hot drying medium. The feed may be solution, slurry, emulsion, gel or paste, provided it is pumpable and capable of being atomized. It involves bringing together a highly dispersed liquid and a sufficient volume of hot air to produce evaporation and drying of liquid droplets. The air supplies the heat for evaporation and conveys the dried product to the collector; the air is then exhausted with the moisture. Three types of atomizers are commercially used namely rotary atomizer, pressure nozzle and two-fluid nozzle. The feed droplets while losing its moisture to hot air remain at temperatures much below the hot air temperature for a very short time. Hence spray drying is essentially known as “Low Temperature Drying”. The dried product can be in the form of powders, granules, or agglomerates depending upon the physical and chemical properties of the feed, the dryer design and final powder properties desired. It is used for “In-House” manufacturing of critical excipients. The spray-dried products have improved mean particle size and particle size distribution, appearance, texture, flow property, compressibility, bulk density, dispersibilty and solubility. It has wide range of non- pharmaceutical and pharmaceutical applications. It is used for preparation of tableting constituents, vaccines, vitamins, blood products, enzymes, hormones, algae, yeast extracts. Spray drying plants are tailor made to suit product to be dried and its properties desired.

Figure- 2 Rotary atomizer[5]

Figure-3 Pressure nozzle[5]

Figure- 4 Two fluid nozzle [4]

Introduction[1-5]

History[1-3]

The development of spray drying equipment and techniques evolved over a period of several decades from the 1870s through the early 1900s. The first known spray dryers used nozzle atomizers, with rotary atomizers introduced several decades later. Because of the relatively unsophisticated designs of the early spray dryers and practical difficulties in operating them continuously, very little commercial use of the process was made until the 1920s.

By the second decade of the twentieth century, the evolution of spray dryer design made commercial operations practical. This process found its earliest widespread acceptance in dairy industry. Milk drying was the first major commercial application of the technology. Spray dryers to produce powdered milk, whey and baby formulas are still one of the largest applications of the technology.

Spray drying is not a new technology as far as the pharmaceutical industry is concerned, having been used successfully for producing drug substances and various excipients since the early 1940s. It was employed primarily in manufacturing of bulk pharmaceuticals and fine chemicals, such as antibiotics, analgesics, antacids, and vitamins.

Spray drying encapsulation has been used in the food industry since the late 1950s to provide flavor oils with some protection against degradation / oxidation and to convert liquids into powders. Spray drying was developed as a convenient method of drying heat-sensitive biological materials, such as enzymes and pharmaceutical proteins, with minimal loss of activity.

Spray drying came of age during World War II, with the sudden need to reduce the transport weight of foods and other materials. This surge in interest led to developments in the technology that greatly expanded the range of products that could be successfully spray dried. It has been used in pharmaceutical technology studies to produce pharmaceuticals excipient with improved compressibility, such as lactose, to improve flow properties, to prepare free-flowing granules for tablet production, to improve the drug aqueous solubility and, consequently, their bioavailability. In addition, a number of formulation processes can be accomplished in one step in a spray dryer; these include complex formation and micro encapsulation. The fact that spray drying greatly reduces the labor-intensive formulation, drying and granulating of solid-dose pharmaceuticals gives cause to review the potential for this process in numerous instances. The pharmaceutical industry, however, is coming under ever-increasing pressure to reduce manufacturing cost, while still maintaining strict purity standards and highest level of quality control.

Figure- 5 Formation of product in spray drying [7]

Figure-6 Aseptic layout of spray drying system[2]; 1 Air, 2 Feedstock 3 Dried product, 4 Drying chamber, 5 Cyclone, 6 Sterile filter for feed, 7 Two-fluid / Pressure nozzle, 8 Prefilter for atomizing air, 9 Prefilter for drying air, 10 Indirect air heater, 11 HEPA filters, 12 Clean room for packing

Figure-7 Scanning electron microscopic photographs of spray-dried chitosan microspheres; a) Uncross-linked, b) cross-linked with d,l-glyceraldehyde.

Concept of spray drying technique

The production of particles from the process of spraying has gained much attention in recent years. These efforts have resulted in spray technology being applied to the manufacture of particles to generate products ranging from pharmaceutical direct compression excipients and / or granulations to microencapsulated flavors.

The two main spray techniques are spray drying & spray congealing. The action in spray drying is primarily that of evaporation, whereas in spray congealing it is that of a phase change from a liquid to a solid. The two processes are similar, except for energy flow. In the case of spray drying, energy is applied to the droplet, forcing evaporation of the medium resulting in both energy and mass transfer through the droplet. In spray congealing, energy only is removed from the droplet, forcing the melted to solidify.

Spray drying is the most widely used industrial process involving particle formation and drying. It is highly suited for the continuous production of dry solids in either powder, granulate or agglomerate form from liquid feedstocks as solutions, emulsions and pumpable suspensions. Therefore, spray drying is an ideal process where the end-product must comply with precise quality standards regarding particle size distribution, residual moisture content, bulk density, and particle shape.

Principle[1, 4-5]

There are three fundamental steps (figure 1) involved in spray drying.

1)Atomization of a liquid feed into fine droplets.

2)Mixing of these spray droplets with a heated gas stream, allowing the liquid to evaporate and leave dried solids.

3)Dried powder is separated from the gas stream and collected.

Spray drying involves the atomization of a liquid feedstock into a spray of droplets and contacting the droplets with hot air in a drying chamber.

The sprays are produces by either rotary (wheel) or nozzle atomizers. Evaporation of moisture from the droplets and formation of dry particles proceed under controlled temperature and airflow conditions. Powder is discharged continuously from the drying chamber. Operating conditions and dryer design are selected according to the drying characteristics of the product and powder specification.

Atomization[2, 4-6]

The atomizing device, which forms the spray, is the ´heart´ of the spray drying process.

Atomizer: Equipment that breaks bulk liquid into small droplets, forming a spray.

Prime functions of atomization are:

a.A high surface to mass ratio resulting in high evaporation rates,

b.Production of particles of the desired shape, size and density.

The aim of atomizing the concentrate is to provide a very large surface, from which the evaporation can take place. The smaller droplets, the bigger surface, the easier evaporation, and a better thermal efficiency of the dryer are obtained. The ideal from a drying point of view would be a spray of drops of same size, which would mean that the drying time for all particles would be the same for obtaining equal moisture content.

Over the years several researches have studied the mechanism by which atomization takes place and several theories have evolved. The most widely accepted are based on the liquid jet theory described in 1878 by Lord Rayleigh. A liquid stream accelerated by the force of gravity is pulled apart or disintegrated into teardrop-shaped droplets. The surface tension of the liquid causes the droplet, suspended in air, to form itself into a sphere.

In order to produce top-quality products in the most economical manner, it is crucial to select the right atomizer. Three basic types of atomizers are used commercially:

a.Rotary atomizer (atomization by centrifugal energy)

b.Pressure nozzle (atomization by pressure energy)

c.Two-fluid nozzle (atomization by kinetic energy)

Ultrasonic energy & vibrations have also been studied, but as yet have found few commercial applications. The selection of a specific atomizer is made based on the properties of the feed, the desired powder properties, the dryer type and its capacity and the atomizer capacity.

Rotary atomizers: Atomization by centrifugal energy [2, 5]

Rotary atomizer (figure 2) uses the energy of a high speed-rotating wheel to divide bulk liquid into droplets. Feedstock is introduced at the center of the wheel, flows over the surface to the periphery and disintegrates into droplets when it leaves the wheel.

Advantages of rotary atomizers:

-Great flexibility & ease of operation.

-Low pressure feed system.

-No blockage problems.

-Handling of abrasive feeds.

-Ease of droplet size control through wheel speed adjustment.

Disadvantages of rotary atomizers:

-Produce large quantities of fine particles, which can result in pollution control problems.

-High capital cost.

-Very expensive to maintain.

-Cannot be used in horizontal dryers.

-Difficult to use with highly viscous materials.

Because of the problems and costs associated with rotary atomizers, there is interest within segments of the spray dry industry in replacing rotary atomizers with spray nozzles.

Pressure nozzles: Atomization by pressure energy [2, 5]

Pressure nozzle (figure 3) is the most commonly used atomizer for spray drying. Nozzles generally produce coarse, free flowing powders than rotary atomizers. Pressure nozzles used in spray drying are called “vortex” nozzles because they contain features that cause the liquid passing through them to rotate. The rotating fluid allows the nozzle to convert the potential energy of liquid under pressure into kinetic energy at the orifice by forming a thin, high-speed film at the exit of the nozzle. As the unstable film leaves the nozzle, it disintegrates, forming first ligaments and then droplets. Pressure nozzles can be used over a large range of flow rates, and can be combined in multiple-nozzle installations to give them a great amount of flow rate and particle size flexibility. The range of operating pressure range for pressure nozzles used in spray drying is from about 250 PSI (17.4 bar) to about 10,000 PSI (690 bar).

Figure-16 Simple spray dryer

Figure-17 Minor spray dryer

Figure-18 Aseptic production minor spray dryer

Figure-19 Mini spray dryer B-290

Two-fluid or Pneumatic nozzles: Atomization by kinetic energy[2, 5]

Liquid feedstock and compressed air (or steam) are combined in a two-fluid nozzle (figure 4). The design utilizes the energy of compressed gas to atomize the liquid. Two advantages of the two-fluid nozzle are its ability to produce very fine particles and to atomize highly viscous feeds. However, two-fluid nozzles are expensive to operate because of the high cost of compressed air. Two fluid nozzles are often used in laboratory and pilot plant spray dry applications because of their ability to produce a wide range of flow rates and droplet sizes. The range of operating pressure range for pressure nozzles used in spray drying is from about 250 PSI (17.4 bar) to about 10,000 PSI (690 bar).

Ultrasonic Atomization[3]

Recently ultrasonic energy has been used in place of pressure or centrifugal force to form droplets. In this method, a liquid is placed on a rapidly vibrating surface at ultrasonic frequencies. At sufficiently high amplitude, the liquid spreads, becomes unstable and collapses, resulting in the formation of very fine droplets. These devices are excellent for droplets below 50 microns. Their use is expected to grow over the next few years.

Mixing and drying[1, 7-8]

Once the liquid is atomized it must be brought into intimate contact with the heated gas for evaporation to take place equally from the surface of all droplets within the drying chamber. The heated gas is introduced into the chamber by an air disperser, which ensures that the gas flows equally to all parts of the chamber.

Air Disperser

The air disperser uses perforated plates or vaned channels through which the gas is directed, creating a pressure drop and, thereby, equalizing the flow in all directions. It is critical that the gas entering the air disperser is well mixed and has no temperature gradient across the duct leading into it. As a result, it is important that any type of heater used inherently produces a well-mixed gas stream, or that a mixing section is placed between the heater and the air disperser. The air disperser is normally built into the roof of the drying chamber and the atomization device is placed in or adjacent to the air disperser. This arrangement allows instant and complete mixing of the heated drying gas with atomized cloud of droplets. To fully understand the characteristics of spray-dried powders, one needs to examine the mechanism for drying within a single droplet (Figure 5). Typically, there are many very small particles suspended in a sphere of liquid. When the droplet is first exposed to hot gas, rapid evaporation takes place. Material dissolved in the liquid will tend to form a thin shell at the surface of the sphere. Although the evaporation has kept the particle itself quite cool, as the liquid concentration decreases, the particle will begin to heat. Evaporation then takes only as quickly as the liquid can diffuse to the surface of the sphere. This phase of the drying process is called first-order drying or is said to be diffusion-rate-limited.

Fortunately, this phase occurs in the cooler part of the dryer where the drying gas is at or near the outlet temperature of the dryer. As a result the solids in each particle are never heated above the outlet temperature of the dryer, even though the dryer inlet may be considerably higher. The final dried powder will be at a temperature approximately 20°C lower than the air outlet temperature.

The thermal energy of the hot air is used for evaporation and the cooled air pneumatically conveys the dried particles in the system. The contact time of the hot air and the spray droplets is only a few seconds, during which drying is achieved and the air temperature drops instantaneously. The dried particle never reaches the drying air temperature. This enables efficient drying of heat sensitive materials without thermal decomposition.

Turbulence within the dryer, which is necessary for good drying, does cause some particles to be exposed to elevated temperature. This sometimes causes a loss in activity or modification of additives such as binders. Therefore, test work is recommended on each formulation, and the best combination of inlet and outlet temperatures needs to be established relatively to activity and performance of the powder in further processing.

Table: 1 Parameters to be controlled

| Sr.No. | Physical properties of feed | Equipment and process parameters | Spray dried product characteristics |

| 1 | Feed concentration increased or High viscosity of polymer | Two fluid nozzle: 10-200 µPressure nozzle: 20-200 µ | Particle size increased with low bulk density |

| 2 | Low surface tension with smaller droplet size | Increased energy of atomization and higher drop velocity | Reduced particle size and better compressibility |

| 3 | Increased temperature of the spray solution with correct drop formation | Increased spray flow rate (to optimum level) | Better flow characteristics |

| 4 | Low concentration (<0.5% w/w) of hydrophilic polymers such as NaCMC and HPMC | — | Improved release rate of a poorly water soluble drug |

| 5 | — | Increased dryer outlet temperature | Lower final product moisture content |

| 6 | — | Multistage and energy recovery units | Suitability for processing heat sensitive pharmaceuticals |

Table: 2 Comparison of spray dryer at laboratory, pilot and commercial scales

| Lab scale | Pilot scale | Commercial scale | |

| Drying gas | Nitrogen / Air | ||

| Type of feed | Aqueous/organic solutions, suspensions or emulsions | ||

| Fit for injectables? | Yes | Yes | Yes |

| Atomization devices | Two-fluid nozzle | Two-fluid nozzle Pressure nozzle |

Two-fluid nozzle Pressure nozzle |

| Nominal drying gas flow (kg/h) | 40 | 80 | 1250 |

| Evaporating capacity(in kg water/hour) | 1 | 6 | 90 |

| Typical batch scale (kg) | 0.01 – 0.500 | 0.2 – 20 | 10 – 1000 |

The drying chamber

The largest and most obvious part of a spray-drying system is the drying chamber. This vessel can be taller and slander or have large diameter with a short cylinder height. Selecting these dimensions is based on two process criteria that must be met. First, the vessel must be of adequate volume to provide enough contact time between the atomized cloud and the heated glass.

The second criterion is that all droplets must be sufficiently dried before they contact a surface. This is where the vessel shape comes into play. Centrifugal atomizer requires larger diameter and less cylinder height. Nozzles are just the opposite. Most spray dryer manufacturers can estimate, a given powder’s mean particle size, what dimensions are needed to prevent wet deposits on the drying chamber walls.

Drying chambers are usually constructed of stainless steel sheet metal, with stiffeners for structural support and vessel integrity. Sheet steel finish and weld polish can be specified to meet any requirement. Insulation is usually applied to the outside of the vessel, and stainless steel wrapping is seam-welded over the entire vessel. This provides a thermally efficient and safe system that is easy to clean has no crevice areas that might become contaminated.

Powder separation[1,7-8]

In almost every case, spray-drying chambers have cone bottoms to facilitate the collection of the dried powder. When the coarse powder is to be collected, they are usually discharged directly from the bottom of the cone through a suitable airlock, such as a rotary valve. The gas stream, now cool and containing all the evaporate moisture, is drawn from the center of the cone above the cone bottom and discharge through a side outlet. In effect, the chamber bottom is acting as a cyclone separator. Because of the relatively low efficiently of collection, some fines are always carried with the gas stream. This must be separated in high-efficiency cyclones, followed by a wet scrubber or in a fabric filter (bag collector). Fines are collected in the dry state (bag collector) are often added to the larger powder stream or recycled.

Parameters to be controlled[2, 4, 9-10]

The pharmaceutical spray-dried products have important properties like

-Uniform Particle size,

-Nearly spherical regular particle shape,

-Excellent Flowability,

-Improved Compressibility,

-Low Bulk Density,

-Better Solubility,

-Reduced Moisture Content,

-Increased Thermal stability, and suitability for further applications.

Such product characteristics majorly depend on the physical properties of feed, equipment components and processing parameters (Table 1). By modifying the spray drying process, it is possible to alter and control the mentioned properties of spray-dried powders. It is certainly very useful for the development of drug delivery systems.

With the latest developments on spray drying technologies and with the increasing demand for highly defined particles properties in the pharmaceutical industry, there have been developed a range of spray drying units (Table 2) able to operate under the most stringent cGMP conditions.

All spray dryers units operate with nitrogen as the drying gas and are fit to handle both aqueous and organic feeds (solutions, emulsions and pumpable suspensions).

Advantages and disadvantages[2,9-11]

In the world of industrial dryers, there are few types that accept pumpable fluids as the feed material at the inlet end of the process and produce dry particulate at the outlet.

The main advantage of spray drying is the remarkable versatility of the technology, evident when analyzing the multiple applications and the wide range of products that can be obtained.

From very fine particles for pulmonary delivery to big agglomerated powders for oral dosages, from amorphous to crystalline products and the potential for one-step formulations, spray drying offers multiple opportunities that no other single drying technology can claim. This flexibility and reproducibility makes spray drying the process of choice for many industrial drying operations.

Advantages of spray drying

1.Able to operate in applications that range from aseptic pharmaceutical processing to ceramic powder production.

2.It can be designed to virtually any capacity required. (Feed rates range from a few pounds per hour to over 100 tons per hour).

3.The actual spray drying process is very rapid, with the major portion of evaporation taking place in less than a few seconds.

4.Adaptable to fully automated control system that allows continuous monitoring and recording of very large number of process variables simultaneously.

5.Wide ranges of spray dryer designs are available to meet various product specifications.

6.It has few moving parts and careful selection of various components can result in a system having no moving parts in direct contact with the product, thereby reducing corrosion problems.

7.It can be used with both heat-resistant and heat sensitive products.

8.As long as they are can be pumped, the feedstock can be in solution, slurry, paste, gel, suspension or melt form.

9.Offers high precision control over Particle size, Bulk density, Degree of crystallinity, organic volatile impurities and residual solvents.

10.Powder quality remains constant during the entire run of the dryer. Nearly spherical particles can be produced, uniform in size and frequently hollow, thus reducing the bulk density of the product.

Disadvantages of spray drying

1.The equipment is very bulky and with the ancillary equipment is expensive.

2.The overall thermal efficiency is low, as the large volumes of heated air pass through the chamber without contacting a particle, thus not contributing directly to the drying.

Applications

Degree of application decides the importance of process. Spray drying technology is widely applied in pharmaceutical fields as well as non-pharmaceutical fields.

Non-pharmaceutical applications[2]

Chemical industry, Ceramic materials, Detergents, soaps and surface-active agents, Pesticides, herbicides, fungicides and insecticides, Dyestuffs, pigments, fertilizers, mineral floatation concentrates, inorganic chemicals, organic chemicals, spray concentration (purification), milk products, egg products, food and plant products, fruits, vegetables, carbohydrates and similar products, slaughterhouse products, fish products and many others.

Pharmaceutical applications

Many pharmaceutical and biochemical products are spray dried, including antibiotics, enzymes, vitamins, yeasts, vaccines, and plasma. The spray drying capacity required for these products ranges from high, in the case of yeasts to low, as in the case of plasma. Spray drying of most pharmaceutical and biochemical products is done using two-fluid or pressure nozzle atomizers. Spray drying systems used for pharmaceutical/biochemical applications include: Open-cycle, aseptic open-cycle (figure 6) and closed-cycle.

Pharmaceutical products[2]

Algae, antibiotics and moulds, bacitracin, penicillin, streptomycin, sulphathiazole, tetracycline, dextran, enzymes, hormones, lysine (amino acids), pharmaceutical gums, sera, spores, tableting constituents, vaccines, vitamins, yeast products, tannin products, etc.

Granulation and tabletting

When compared with other granulation methods, spray drying stands out as unique in several ways. Because the feed to a spray dryer is a homogenous liquid, it eliminates the concern over blending of dry components with liquids.

Although it is the application of shear forces in the centrifugal atomizer that creates a spray, this form of energy generally will not destroy microencapsulated material as can happen in high shear granulators. Spray drying technique has been used for granulating, for slow-release granulations of magnesium carbonate, theophylline and acetaminophen.[1]

The spherical composite particles consisting of amorphous lactose and sodium alginate were prepared by spray drying their aqueous solutions using rotary atomizing spray-dryer. The SD composite particles had good compactibility and excellent micrometric properties as filler for direct tableting of controlled release matrix tablets.[12]

By spray-drying Amioca® starch and Carbopol® 974P mixtures a range of potential bioadhesive carriers was obtained with excellent bioadhesive properties.[13] Solid dispersions of theophylline with chitosan as a carrier were prepared using a spray-drying method.[14]

Modified extended release matrix tablet were produced by compressing material made by spray-drying Theophylline[15] slurried in an aqueous ammoniated solution of cellulose enteric polymers such as cellulose acetate phthalate. Both enteric release and sustained release can be achieved. Spray drying allowed the rapid formation of theophylline polymer micro particles without exposing the material to high temperatures.

Aerosol formulation

Salbutamol sulphate particles, for use in dry powder aerosol formulation, were prepared by spray drying, using a Mini spray dryer[16]. Spray-freeze-dried liposomal ciprofloxacin powder for inhaled aerosol drug delivery had been prepared with a two-fluid nozzle.[17]

Micro particles

Recently, the process received great attention in the field of micro particles[3, 18-19] for the preparation of dried liposomes, amorphous drugs, mucoadhesive microspheres, drying of preformed microcapsules, Gastroresistant microspheres, and controlled-release systems.

Comprehensive studies have been performed on the preparation of microspheres by spray drying techniques for different purposes, like modification of biopharmaceutical properties, formulation of dry emulsions, spray dried phospholipids, nanoparticle-loaded microspheres, for drug delivery, spray-dried powders formulated with hydrophilic polymers, biodegradable microspheres, and spray-dried silica gel microspheres. Eudragit RL microspheres[20] containing vitamin C were prepared by Spray drying method.Spray-drying was useful for the preparation of Paracetamol encapsulating Eudragit RS/RL or Ethylcellulose microspheres.[21]

The spray drying technique has been widely applied to prepare micro-particles of drug with polymer. When a drug crystal suspension of a polymer solution is spray-dried, microcapsulated particles are prepared, whereas spray drying of solution of polymer containing dissolved drug leads to formation of drug-containing microspheres in which the drug can be dispersed in a molecular state or as micro crystals. In both cases, the particles tend to have a spherical shape and are free flowing. These properties are preferable pharmaceutical manufacturing process such as tabletting and capsule filling.

Controlling microsphere size is an important process variable that can affect product performance. Scanning Electron microscope (SEM) is used to characterize the size of microspheres (figure 7). The conventional method of sizing involves periodic sampling and subsequent analysis using off-line techniques, but these have limitations such as late feedback response times, sampling errors and lacks the sensitivity required for it to be used in the detection of fluctuations. Using PAT as an in-process monitor during spray drying could offer better process control and improved product quality resulting in products of greater value. Thus, PAT serves as a useful tool to provide real time information about process and product size.[22]

Micro particles of diltiazem hydrochloride with ethyl cellulose (EC) were prepared by using spray drying technique. Drug was dispersed in benzene solution of EC or dissolved in methanol solution of EC with 1:1-1:5 drug EC ratio, followed by spray drying. A microcapsule structure was obtained in the suspension system, while a microsphere structure, while the drug was in an amorphous state, was formed in the solution system.

Figure-8 Co-current flow dryer

Figure-9 Counter-current flow dryer

Figure-10 Mixed flow dryer

Figure-11 Open cycle flow dryer; 1 Feed storage, 2 Pump, 3 Drying chamber, 4 Air heater, 5 Cyclone, 6 Gas scrubber, 7 Separator

Coating applications

Spray drying has proved extremely useful in the coating and encapsulation of both solids and liquids. Spray-dried micro particles of theophylline were prepared with a coating polymer[23] in an aqueous system. Hydroxypropyl methylcellulose (1.25%w/v) and the drug (0.25w/v) were dissolved in water and spray-dried using a laboratory spray dryer equipped with a two-fluid pressure nozzle.

The spray drying method can produce discrete particles coated with an aqueous coating solution or dispersion from spray droplets of the aqueous solution or suspension of drug and coating polymer when sprayed into a drying chamber. As the solvent is evaporated the coating material envelops the suspended particle. The coating provides such valuable characteristics as taste and odour masking, improvement in stability, enteric coating and sustained release. Oily liquids may be encapsulated by emulsification in water with the aid of a gum such as acacia, or starch, and subsequent spray drying. As the water evaporates, the oil is entrapped in a shell of the gum. This process is used for the preparation of “dry” flavor oils[24].

Dry emulsions and dry elixirs

Dry emulsions[25]were prepared by spray drying various liquid o/w emulsions containing fractionated coconut oil dispersed in aqueous solutions of HPMC (solid carrier). Flurbiprofen (FP) dry elixir[26] prepared by the spray-drying technique showed good flowability and was spherical in shape, having a geometric mean diameter of about 13 μm. Dry elixir is a solid form of microcapsules simultaneously containing ethanol and drug in water-soluble polymer shell. The dry elixir was produced when a solution of water-soluble dextrin and drug dissolved in an ethanol-water co-solvent system was spray-dried. The final solutions were delivered to the nozzle at a flow rate of 5 ml/min using a peristaltic pump and thereafter spray-dried.

Inlet and outlet temperatures were maintained at 90 and 55°C respectively. The poorly water-soluble drugs encapsulated in the dry elixir are readily dispersed and dissolved in aqueous media as a result of the co-solvent effect of ethanol, resulting in enhanced dissolution rate & bioavailability.

Types of spray dryer systems [2]

On the basis of the type of flow

Co-current flow dryer

In the co-current flow dryer (figure 8), the spray is directed into the hot air entering the dryer and both pass through the chamber in the same direction. Spray evaporation is rapid, and the temperature of the drying air is quickly reduced by the vaporization of water. The product does not suffer from heat degradation since once the moisture content reaches the target level, the temperature of the particle does not increase greatly because the surrounding air is now much cooler. Dairy and other heat-sensitive food products are preferably dried in co-current dryers.

Counter-current flow dryer

In this dryer design (figure 9), the spray and the air are introduced at opposite ends of the dryer, with the atomizer positioned at the top and the air entering at the bottom. A counter-current dryer offers more rapid evaporation and higher energy efficiency than a co-current design. Because the driest particles are in contact with hottest air, this design is not suitable for heat-sensitive products. Counter-current dryers normally use nozzles for atomization because the energy of the spray can be directed against the air movement. Soaps and detergents are commonly dried in counter-current dryers.

Mixed flow dryer

Dryers of this type combine both co-current and counter current flow. In a mixed flow dryer, the air enters at the top and the atomizer is located at the bottom. Like the counter-current design, a mixed flow dryer (figure 10) exposes the driest particles to the hottest air, so this design is not used with heat-sensitive products.

On the basis of the type of cycle

Open cycle dryer

In an open cycle dryer (figure 11), drying air is drawn from the atmosphere, heated, conveyed through the chamber and then exhausted to the atmosphere. This is by far the most commonly used design.

Closed cycle dryer [27]

A closed cycle dryer (figure 12) recycles the drying gas, which may be air or more commonly, an inert gas such as nitrogen. Closed cycle units are the dryers of choice when:

i.Feedstock consists of solids mixed with flammable organic solvents.

ii.Complete recovery of solvent is required.

iii.The products are toxic

iv.Pollution due to vapor, particulate emissions or odor is not permitted.

v.Explosion risks must be eliminated.

vi.The powder will degrade by oxidation during drying.

Semi-closed cycle dryer

This dryer design (figure 13) is a cross between open and closed cycle dryers. A direct-fired heater is used and the air entering the system is limited to that required for combustion. An amount of air equal to the combustion air is bled from the system at the other end of the process. The gas (mainly products of combustion) is recycled through the dryer. The recycled gas has very low oxygen content, making it suitable for materials that cannot be exposed to oxygen, due to explosive hazard or product degradation.

On the basis of the type of stage

Single stage dryer

In a single stage dryer, the moisture is reduced to the target (typically 2-5% by weight) in one pass through the dryer. The single stage dryer is used in the majority of designs.

Two stage dryer

In a two stage dryer (figure 14), the moisture content of product leaving the chamber is higher (5-10%) than for the final product. After leaving the chamber, the moisture content is further reduced during a second stage. Second stage drying may be done in a fluidized bed dryer or a vibrating bed dryer. Two stage dryers allow the use of lower temperatures in the dryer, making the design a good choice for products that are particularly heat sensitive.

On the basis of the position

Vertical dryer

The chamber of a vertical (tower) dryer has the form of a tall cylinder with a cone-shaped bottom. Spray nozzles may be located at the top (co-current flow) or bottom (counter-current or mixed flow) of the chamber. Inlets for the drying air may be located at the top, bottom or side of the chamber. Vertical spray dryers are usually large and the residence time of sprayed particles is relatively long, allowing the use of higher flow nozzles such as the TD, which produce relatively large particles.

Horizontal dryer

The chamber of a horizontal dryer (figure 15) has the form of a rectangular box with either a flat or a “V” shaped bottom. Nozzles in a box dryer normally spray horizontally, with the dried particles falling to the floor, where they are removed to a bagging area by a sweep conveyor or screw conveyor. Box dryers are usually small and the particle residence time relatively short, requiring the use of low flow nozzles, which produce relatively small particles.

Figure-12 Closed cycle dryer

Figure-13 Semi-closed dryer; 1 Combustion air, 2 Coolant, 3 Feedstock, 4 Heater fuel, 5 Condensed water discharge, 6 Dried product, 7 Drying chamber, 8 Cyclone, 9 Direct heater (gas), 10 Heat exchanger, 11 Scrubber/condenser, 12. Air bleed to atmosphere

Figure-14 Two stage dryer; 1 Air, 2 Feedstock, 3 Dried product, 4 Drying chamber, 5 Cyclone, 6 Stationary fluid bed, 7 Fluid bed cyclone, 8 Transport cyclone

Figure-15 Horizontal dryer, 1. Drying air, 2 Feedstock, 3 Pneumatic conveyor, 4 Drying chamber, 5 Powder conveyor, 6 Filter bags, 7 Cyclone, 8 Dust return, 9 Exhaust to atmosphere, 10 Dried powder

Equipments[11, 12, 28]

Different Spray Dryer Models are available commercially.

Simple spray dryer (figure 16)

-Largest standard plant.

-For small scale production.

-Rotary wheel or nozzle atomizers.

-One-or two-point product collection.

-Can be readily modified.

-Direct-fired gas or electric heat.

-Evaporation rates to 60 kg/hr.

Minor spray dryer (figure 17)

-Versatile Spray Dryer for in-house research and small scale production.

-Interchangeable atomization and powder discharge systems.

-Sanitary design.

-Standard modules for a wide range of configuration.

Aseptic production minor™ spray dryer(figure 18)

-Easily sterilized.

-Electrically heated.

-HEPA filtration oninlet air.

-Positive pressure system.

-316L stainless product contact.

-Separate powder discharge box.

-Water evaporation to 18 kg/hr.

Mini spray dryer B-290

The Mini Spray Dryer B-290 (figure 19) is the laboratory equipment of your choice for the quick and gentle drying to powder of liquid end products. The impressive features of the Spray Dryer include its efficient performance with very short set-up times, an effective integrated nozzle cleaning mechanism and a high degree of flexibility due to the different cylinder geometries. The B-290’s outstanding features greatly extend the number of applications that are possible with a spray drying process.

Applications:

-Spray drying from solutions

-Structure modifications

-Drying of suspensions

-Agglomeration

-Spray crystallization

-Micro-encapsulation and coating

Fluidized spray drying

Powders with a mean particle diameter larger than 15 micron can usually be said to be free-flowing and non dusty. Such powders can be easily fed to conventional tableting equipment, producing equivalent, or in some cases better, quality tablets than other granulation methods. Most of the pharmaceutical granulation is still done batch wise and usually results in larger particles than spray dryers produce.

One of the most popular of these techniques is fluid bed spray granulation. It combines features of both spray drying and fluid bed granulation to achieve continuous process that produces granules similar to those obtained from fluid bed granulation process. This process is called fluidized spray drying (FSD). The Fluidized Spray Dryer is one of the most successful designs of spray dryers ever developed

Principle

The chamber is shaped as a slender cone with a short cylindrical section. The operation is much like conventional spray dryer. However the bottom cone of the spray dryer has been modified to include an integral fluid bed. In the upper part of FSD (Figure 20), atomization and mixing with heated air takes place as usual. However, when the partially dried particles fall from drying gas, they are captured in fluidized bed. Controlled temperature and humidity conditions in the bed allow the particles to stay moist enough to agglomerate. Each of these agglomerates are a cluster of individual partially spray dried droplets. Obviously, there are going to be some droplets that dry completely without agglomerating. In addition the fluidizing action in the fluid bed will create some attrition. Fines from both sources will tend to be carried towards the drying gas exhaust point. In the FSD, all drying gas from both the hot air inlet and the fluidized bed leave the drying chamber through two exhaust ducts in the roof. As a result, fines entrained in the gas stream have to pass through the atomized spray, affording even greater opportunity for agglomeration. Fines that do escape the drying chamber are collected in cyclones or a bag collector and pneumatically re-injected into the dryer. As a result there are no fines left to recycle or discard.

Advantages

1.Dustless, coarse, free-flowing product with good re-dispersibility.

2.Trouble-free drying of many thermoplastic and/or hygroscopic products.

3.Very compact plant layout improves energy economy with higher inlet and lower outlet drying temperatures.

4.Excellent for agglomerated or granulated products.

5.Aseptic and/or closed-cycle design available.

6.Drying of heat-sensitive and aromatic products without degradation.

Spray freeze drying (figure 21)

It is the method, which combines processing steps common to freeze-drying and spray-drying.

Potential uses

-Bioactive extracts from milk/whey.

-Freeze dried coffee/tea.

-Fruit juices.

-Pharmaceuticals/Nutraceuticals. (figure 22)

Major advantages

-Continuous process.

-Greater energy efficiency.

-Much shorter drying times.

-Less labour intensive.

Figure- 20 Fluidized spray dryer

Figure-21 Spray freeze drying

Figure-22 Scanning electron microscopic photograph of (a) spray-freeze-dried Mannitol (b) spray- freeze-dried trehalose

Conclusion

Spray drying can be advantageous route to pharmaceutical manufacture. In the production of powders for direct compression tableting, this process continuously produces a product of uniform composition and controllable physical properties. Its applicability is extended from critical excipients to micro encapsulation, aqueous coating, dry emulsions and dry elixirs. It can often replace several steps from a traditional batchwise process and eliminate a considerable amount of operator handling.

References

1.Parikh D, Spray drying as a granulation Technique; In: Handbook of Pharmaceutical Granulation Technology, Drugs and the Pharmaceutical Sciences. New York, Marcel Dekker.1997; 75-96.

2. http://www.bete.com/pdfs/BETE_SprayDryManual.pdf/ accessed on November 11, 2008

3.Maria-Ineˆs Re´. Formulating Drug Delivery Systems by Spray Drying, Drying Technology 2006, 24, 433-446.

4.Swarbrick J, Boylan J; Spray drying and Spray Congealing of Pharmaceuticals; In:Encyclopedia of Pharmaceutical Technology, Marcel Dekker. 1992; 207-221.

5. http://www.niroinc.com/html/drying/fdspraychem.html/ accessed on November 11, 2008

6. http://www.niroinc.com/html/drying/atom.html/ accessed on November 11, 2008

7. http://www.acmefil.co.in/spraydryer.html/ accessed on November 11, 2008

8.Aulton M, Drying, In: Pharmaceutics – The Science of Dosage Form Design, Churchill Livingstone. 2002; 390.

9.Oral Solid Dosage Forms; In: Remington – The Science and Practice of Pharmacy, 1995; 1627-1628.

10. http://www.hovione.com/galenic/spraydry.asp/ accessed on November 11, 2008

11. http://www.spraydrysys.com/whyspraydry.htm/ accessed on November 11, 2008

12.Hirofumi, Takehiko, Tomoaki, Hiromitsu, Yoshiaki. Spray-dried composite particles of lactose and sodium alginate for direct tabletting and controlled releasing, International Journal of Pharmaceutics,1998, 174, 91-100.

13.Ameye D, Musa D, Foreman P, Remon J. Spray-dried Amioca® starch/ Carbopol® 974P mixtures as buccal bioadhesive carriers, International Journal of Pharmaceutics, 2005, 301, 170-180.

14.Tanino H, Danjo K, Asada M, Takahashi H, Okamoto H. Theophylline particle design using chitosan by the spray drying, International Journal of Pharmaceutics, 2004, 270, 167-174.

15.Rowe R, Defects in Aqueous Film-Coated Tablets; In: Aqueous Polymeric Coatings for Pharmaceutical Dosage forms, Drugs and the Pharmaceutical Sciences. New York, Marcel Dekker.1997; 419-441.

16.Chawla A, Taylor K, Newton J, Johnson M. Production of spray dried Salbutamol Sulphate for use in dry powder aerosol formulation, 233-240.

17.Sweeney L, Wang Z, Loebenberg R, Wong J, Lange C, Finlay W. Spray-freeze-dried liposomal ciprofloxacin powder for inhaled aerosol drug delivery, International Journal of Pharmaceutics, 2005, 305, 180–185.

18.Palmieri G, Wenrle P, Stamm A. Evaluation of spray-drying as a method to prepare micro particles for controlled drug release, Drug Development and Industrial Pharmacy, 1994, 20(18), 2859-2879.

19. http://www.niroinc.com/food_chemical/chem_pilot_plants.asp/ accessed on November 11, 2008

20.Espositoa E, Cervellatib F, Menegattia E, Nastruzzic C, Cortesia R. Spray dried Eudragit micro particles as encapsulation devices for vitamin C, International Journal of Pharmaceutics, 2002, 242, 329-334.

21.Palmieri G, Bonacucina G, Martino P, Sante Martelli. Spray-Drying as a Method for Microparticulate Controlled Release Systems Preparation: Advantages and Limits. I. Water-Soluble Drugs, Drug Development and Industrial Pharmacy, 2001, 27(3), 195-204.

22.Hui T, Wah C, Heng P. Rapid and convenient microsphere sizing, Pharmaceutical Technology Asia Pacific, 2008, 2(3), 25-29.

23.Lachman L, Lieberman H, Kanig J. Drying, The Theory and Practice of Industrial Pharmacy. Varghese Publishing House, Bombay.1991; 60-61.

24.Steven H, Wu W, Wyatt D, Adams M. Chemistry and Application of Cellulosic Polymers for Enteric Coating of Solid Dosage forms; In: Aqueous Polymeric Coatings for Pharmaceutical Dosage forms, Drugs and the Pharmaceutical Sciences, Marcel Dekker.1997, 385-418.

25.Christensen K, Pedersen G, Kristensen H. Preparation of redispersible dry emulsions by spray drying, International Journal of Pharmaceutics 2001, 212, 187–194.

26.Kim C, Yoon Y, Kong J. Preparation and evaluation of flurbiprofen dry elixir as a novel dosage form using a spray-drying technique, International Journal of Pharmaceutics 1995, 120, 21-31.

27. http://www.niroinc.com/pharma_systems/pharmaceutical_spray_dryer.asp/ accessed on November 11, 2008

28. http://www.laborpartner.at/pdf/BUCHI_Mini_Spray_Dryer_B290_dt.pdf/ accessed on November 11, 2008

29. http://www.niroinc.com/food_chemical/fluidized_spray_dryer.asp/ accessed on November 11, 2008

30.http://www.pharmainfo.net/free-books/fluidized-bed-systems-review accessed on November 11, 2008

96,956 total views, 2 views today

LinkedIn

LinkedIn Facebook

Facebook Twitter

Twitter GooglePlus

GooglePlus