.jpg?n=3254)

Approximately two years ago the EMA published a draft guideline on process validation for the manufacture of biotech products. Now the final guideline has been published under the title “Guideline on process validation for the manufacture of biotechnology-derived active substances and data to be provided in the regulatory submission“.

READ

Approximately two years ago the EMA published a draft guideline on process validation for the manufacture of biotech products. Now the final guideline has been published under the title “Guideline on process validation for the manufacture of biotechnology-derived active substances and data to be provided in the regulatory submission”.

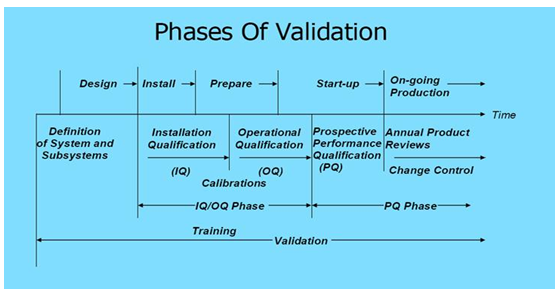

The scope of the guideline is to provide guidance on the data to be included in a regulatory submission to demonstrate that the active substance manufacturing process is in a validated state. The guideline focuses on recombinant proteins and polypeptides, their derivates, and products of which they are components (e.g. conjugates). But it is explicitly mentioned that the principles could also be applied to vaccines or plasma-derived products and other biological products, as appropriate.

Process validation is mentioned as life cycle, comparable to Annex 15 and to the EMA guideline on process validation for finished products . Also comparable to both, the guideline offers a traditional or an enhanced (with reference to ICH Q 11) approach to process validation. A combination of both approaches is possible as well. This “hybrid approach” is in line with the other new European process validation guidelines, too.

Process validation is divided into two parts:

- process characterisation, where the commercial manufacturing process is defined

and

- process verification, where the final manufacturing process as established based on process evaluation studies performs effectively in routine manufacturing.

Process characterisation itsself is also divided into two parts:

- process development, which includes studies to reach a potential design of a future manufacturing process

and

- process evaluation which includes studies on small and/or commercial scales, providing evidence that the complete manufacturing process has been appropriately designed to design the full operating ranges of the manufacturing process.

It is explicitly mentioned that subsequent to succesfull process validation product quality and process performance must be maintained in a state of control during routine production. This ongoing process verification is normally not part of submission data, with the exception of e.g. niche products, which could not be fully validated at the time of the regulatory submission.

There is no number of validation runs mentioned in this guideline and concurrent validation could be considered only in exceptional circumstances (e.g. medical need is mentioned) and after consultation with the regulatory authorities.

Please find further information in the “Guideline on process validation for the manufacture of biotechnology-derived active substances and data to be provided in the regulatory submission”

/////EMA, publishes, finalised, Process Validation Guideline, Biotech Products

Sorry, the comment form is closed at this time.